Genetic Reconfigurable Object Nets (Gen-RONs):

RONs meet Evolution

Researchers: Manel Houimli, Laid Kahloul, Mohamed Khalgui

Visitors

Description:

This project aims to combine the Petri nets (PNs) formalism with genetic algorithms and evolutionary methods. This combination of the two approaches provides a new formalism able to model the system, formally, to verify the properties of the system using model-checking, and to make optimization in the systems using genetic algorithms. Gen-RONs is the combination of Gentic algorithms and Reconfigurable Object nets. Gen-RONs inherits the characteristics of RONs able to model and analyze reconfigurable systems (such as Reconfigurable Manufacturing Systems) and the characteristics of genetic algorithms able to optimize reconfigurable systems (optimizing: time, cost, throughput, etc). This page shows a prototype of a tool realized based on the approach Gen-RONs. The above video represents a demonstration of its use.

Case study:

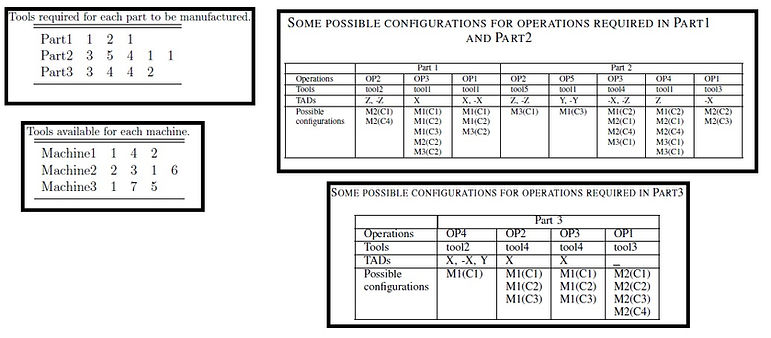

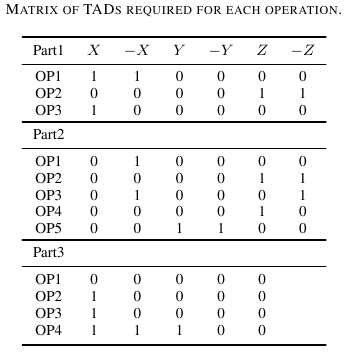

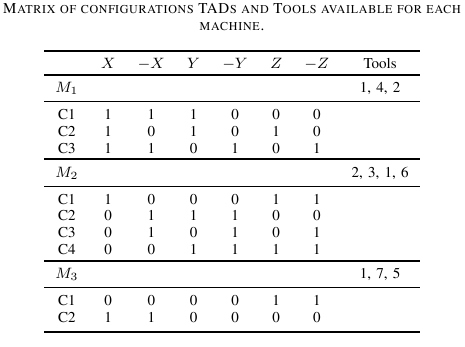

The case study is a reconfigurable manufacturing system inspired by the system described in [7]. The RMS consists of a set of 3 reconfigurable machines that offer varied functionalities according to their various configurations. Each machine has a certain number of available tools and can perform only the operations which their functionalities are available (tool and configuration). The configurations of machines determinate the tool approach directions (TAD) providing the available degrees of freedom (motion along x, y and z axis). A case of a single product with three independent parts is considered. Each part has a set of operations to be carried out respecting the precedence relationship between these operations. Tables below present some information about this case study.

Software prototype:

As presented in the above video, the prototype is composed of three basic files. An HTML page, used as an interface to allow user entering required data, a PHP page working as an interface between the HTML page and the kernel realized in Python 3.7.

The prototype will be uploaded soon and it will be accessible through a web page, as shown in the demonstration.

Basic references:

[1] M. Houimli, L. Kahloul, and M. Khalgui, “Multi-objective optimization and formal specification of reconfigurable manufacturing system using adaptive NSGA-II,” in Proc. Embedded & Distributed Systems (EDiS), 2017 First International Conference on, pp. 1–6, IEEE, 2017.

[2] L. Kahloul, S. Bourekkache, and K. Djouani, “Designing reconfigurable manufacturing systems using reconfigurable object Petri nets,” International Journal of Computer Integrated Manufacturing, vol. 29, no. 8, pp. 889–906, 2016.

[3] H. Ehrig and J. Padberg, Graph Grammars and Petri Net Transformations, pp. 496–536. Berlin, Heidelberg: Springer Berlin Heidelberg, 2004.

[4] Y. Hafidi, L. Kahloul, M. Khalgui, Z. Li, K. Alnowibet, and T. Qu, “On methodology for the verification of reconfigurable timed net

condition/event systems,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, no. 99, pp. 1–15, 2018.

[5] W. Lakhdhar, R. Mzid, M. Khalgui, Z. Li, G. Frey, and A. Al-Ahmari, “Multiobjective optimization approach for a portable development of reconfigurable real-time systems: From specification to implementation,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, 2018.

[7] A. Bensmaine, M. Dahane, and L. Benyoucef, “A non-dominated sorting genetic algorithm based approach for optimal machines selection in reconfigurable manufacturing environment,” Computers & Industrial Engineering, vol. 66, no. 3, pp. 519–524, 2013.